Sales 1 Wen Haimin :13939207678

Sales 2 Zhang Xiaowei :18939286663

Sales 3 Zhang Xiaochao:13939277678

Fax:0392-2568115

Copyright © shuangmin.com All Rights Reserved 豫ICP备11007872号

Development and prospect of mine hoist

Mineral exploitation and transportation is the important link in the process of mineral production, the mine hoist as the key mining transportation equipment, to undertake the rise and fall of an improvement of coal and ore, personnel, materials and equipment of transport task, is an important equipment of contact underground and ground.

China's coal reserves are extremely rich, ranking the highest in the world, and it is the safeguard energy of China's sustainable economic development, which plays a leading role in China's energy system. The production quantity of mine hoist in China is mainly related to the demand of coal mine, especially large and special mine hoist.

1. Development of domestic hoist

The design and manufacture of lifting equipment in our country was originally modeled after the former Soviet union, then developed to its own design and manufacture. In 1953, fushun heavy machinery co., LTD. Made our country's first single-rope winding double drum hoist. In 1958, luoyang mining machinery design and manufacture of the units 1 well tower JKM2 x 4 multi rope friction hoist, design and production of the 1 1960 Wells tower JKM3 x 4 multi rope friction hoist, and gradually form batch production ability, to get rid of the dependence on imported situation.

Since the 1970s, the structural defects of the generic hoist have become more and more prominent. Luoyang mining machinery works began to re-examine our country the status quo and development direction of mine hoist, the some of the new structure of the test and research, on this basis, draw lessons from foreign new technology of mine hoist, especially the plate shape control technology, designed the first large single rope mine hoist, drum diameter 6 m.

In addition, with the wide application of the tower type multi-rope lifting machine, its limitations are gradually revealed, such as the installation of the hoist in the reinforced concrete well tower, its seismic resistance is not as much as the steel structure well frame; When the mine is in the zone of sand and geological conditions, the structural steel structure of the reinforced concrete well tower is adopted. In 1977, luoyang mine machinery factory developed the first floor type JKMD2 x 2 multi-rope friction hoist in China.

In the late 1980 s, through the introduction of some foreign new technology, luoyang mining machinery works has to produce all kinds of new large mine hoist, including motor hanging straight league form large multi rope friction hoist, the friction wheel diameter 4 m. In order to achieve standardization, universalization and serialization, luoyang mine machine factory has developed the national standard of single rope winding and multi-rope friction hoist.

In the late 1990 s, along with the mining of the mine is becoming more and more to develop in the direction of large-scale, high yield, multi rope friction hoist is increasingly become the dominant mining equipment, especially large multi rope friction hoist, because of the significant advantages by mining the user's welcome. At the same time, with the continuous improvement of control technology, it is urgent to develop a new generation of large multi-rope friction hoist with advanced technology, reliable performance and high efficiency and energy saving. In 1999, citic heavy industry machinery co., LTD (hereinafter referred to as citic heavy industry) started to develop and succeed in 2001 made the specifications of the largest in the form of double motor straight league JKMD - 5.7 x 4 floor type multi rope friction hoist, the friction wheel diameter 5.7 m, is the domestic first adopts double motor hanging straight league form of multi rope friction hoist, changed the situation of our country's oversize hoist dependent on imports.

In recent years, with the comprehensive upgrade citic heavy industry technology equipment, equipment specifications, performance and precision of the equipment has been fully upgrade, to improve the product manufacturing process is also larger, in product development further in line with international standards on the means and methods. From 2008 to 2008, citic heavy industries more than 200 sets per year in the number of various specifications and types of hoist supply the domestic market, and exported to Bangladesh, Iran, venezuela, Turkey, Pakistan, and Zambia, and many other countries. In 2014, citic heavy industry exports to polish one large floor JKMD5.5 x 4 p Ⅳ multi rope friction hoist, the friction wheel diameter is 5.5 m, with double motor drive, straight hanging connection mode.

In recent years, the technology level of mine hoist in China although the gap compared with developed countries more and more small, but it's always there, especially in some product performance, quality, and provide solutions for specific users to solve the problem of personalized ability, etc. At present, China still imports some mine hoist every year, although the import amount is not big, but its electric control system import amount is relatively more.

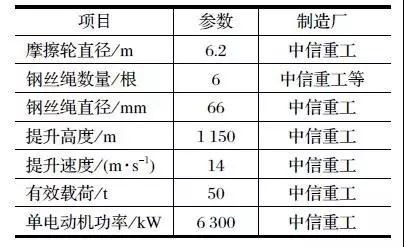

At present, the most representative technical parameters of domestic hoist are listed in table 1.

Table 1 the maximum technical parameters of domestic multi-rope friction hoist

The development of foreign hoist

The development of foreign hoist has a history of over 150 years. The representative period was: in 1827, the western countries appeared in the first steam-type elevator; In 1877, the first single rope friction hoist was manufactured. In 1905, due to the development of electric power, there appeared the first electric drive of the mine hoist, and gradually replaced the steam lift machine; In 1938, the first multi-rope friction mine hoist was introduced. In 1957, the multi-rope winding elevator came out.

In order to adapt to the mine to the deep development (deep) as well as the annual output has been growing demand, multi rope friction hoist can be developed, it is using a few root diameter finer wire rope, instead of only 1 original root diameter of thicker wire rope to ascend.

By 1948, there were only six lift machines in the world, and by the end of 1959, there were more than 240. The Swedish company ASEA, from 1938 to 1972, made 224 friction-type machines, supplying 23 countries, with 4 line hoist accounting for 57% of the total. In 1968, we began to supply 6 rope hoist, accounting for 10%; In 1972, the supply of 8 ropes and 10 rope hoist accounted for 5%. By 1974, it was estimated that more than 600 multi-rope friction lift machines were operating around the world.

Although multi-rope friction hoist was originally used in deep well lifting, many countries are now preferred in shallow well lifting. At present, the multi-rope friction upgrade has become one of the development directions of modernization, and it is developing towards the direction of large scale and full automation.

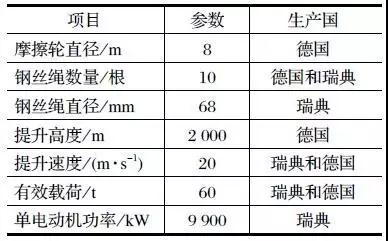

According to the data, the maximum technical parameters of the typical multi-rope friction hoist abroad are listed in table 2.

Table 2 technical parameters of foreign multi-rope friction hoist

3 built-in lifting machine

It is a new type of elevator for mechanical and electrical integration, which is different from the transmission form of conventional hoist. The connection is not simply put the motor in the friction wheel, but the mechanical and electrical parts, friction wheel as external rotor motor, at the same time have the double function of bearing steel wire rope load; Coaxial concentric arrangement with friction wheel motor stator, the friction wheel shaft at the same time as the axis of the motor stator, rotor, stator, friction wheel and motor, motor in two main bearing right in the middle, reducing the factors affecting motor eccentricity, improve the safety and reliability of the operation.

In 1988, the world's 1st built-in lift machine was put into operation at the New Ramberg mine in Germany. The mechanical part of the lifting machine is manufactured by Germany's GHH company, and the electric control part is made by Siemens. The diameter of the friction wheel is 6.5 m, and the rated power of the motor is 2 200 kW. The lifting machine embodies high mechanical and electrical integration and high mechanical and electrical integration, so that the driving technology of the hoist enters a new stage, which brings the attention of domestic and foreign counterparts.

The built-in lifting machine has the following advantages:

(1) the structure is compact and the motor does not need to be installed base, which reduces the floor area of the machine room, especially for the tower elevator, which can reduce the cost of the well tower.

(2) the torque of the motor is transmitted directly to the shell of the friction wheel, with short transmission chain and high transmission efficiency;

(3) the force on both sides of the spindle device is symmetrical, so that the main shaft and bearing force are evenly distributed, while improving the stiffness of the spindle.

(4) it is not necessary to adopt the motor rotor suspension structure, which reduces the deflection of the spindle, reduces the gap between the rotor and stator of the motor, and makes the operation more stable.

(5) the temperature rise of the motor will not cause asymmetry, which will not affect the air gap of the motor.

(6) mechanical and electrical integration, small maintenance and low running cost.

The disadvantage of built-in hoist is that the equipment is expensive. In 2005, two sets of tower type 4.65 x 6 built-in hoist were introduced in liuzhuang mine in xinji, which cost more than 200 million RMB.

In China, the in-built elevating machine is imported in all foreign countries, and in 1994, a floor-type 4.3-m hoist was introduced by the donghuan tuo mine auxiliary shaft. In 1995, yanyan coal company was introduced to 1 tower type 4 m elevator; In 1996, the mine main shaft of Chen silou mine in yongxia mine was introduced into a floor-type 4 m elevator, which was manufactured by the German company simarag.

, although at present our country mounted elevator manufacturing is still in the blank, but built in hoist is hoist in the development of a new form, is the combination of mechanical and electrical perfect, and it will and straight league form of hoist exist at the same time, will not replace straight association-like hoist. In the selection of the connection mode of the hoist, it is usually necessary to consider the price of the equipment and the reliability of operation.

The development prospect of 4 km deep well

At present, the depth of coal mining in China is generally less than 800 m, and a large amount of coal has not been developed because it is buried more than 1,000 m underground. With the rapid development of economy, the demand for energy in the society is increasing, and the mining of deep Wells in coal mines has become a problem that the world's major coal mining countries need to face and solve. According to statistics, the mining depth of coal in China is about 500 m on average, and it is developing at the speed of 8 ~ 12 m per year. In the next 10 years, the mining depth of our mines will reach 10,000 to 2,000 m.

In the early 1980s, German coal mining reached a depth of 1 443 m. By the mid-1980s, there were at least 79 mines deep in the country. In 1977, the opening depth of coal mine in zhaozhuangzhuang of our country reached 154.4 m. At present, there are at least 17 mines in China with a depth of more than 1,000 meters.

Multi rope friction hoist used in deep well, because the elevator wire rope extended, not only increase the working load, and tension in deep well under the condition of wire rope for change is too big, it will be a sharp drop in life and it become the main factors of the mine safety and efficiency. Deep well common problems are: hoisting ropes broken wires and uneven, early effective metal wire rope cross section decreases, and tensile strength is reduced, the overall breaking force drops, etc., makes the shorter service life of wire rope. If the lifting height of tongling dongguashan copper mine is 1 100 m, the average life of the steel wire rope is about 3 months. The hoisting height of the hoisting machine of the main shaft of the small building in pangzhuang in xuzhou is 1 039.6 m, and the average life of the wire rope is 6 months. Therefore, the domestic multi-rope friction hoist is not recommended to be used in a depth of more than 1, 200 m.

In general, for deep well, can use segmented promotion way, namely USES the mature single rope winding hoist or multi rope friction hoist sublevel, technology is easy to implement, but the required equipment is more, the production and management costs will increase obviously, and increase the probability of failure; Another way is to use Mr Blair hoist (that is, the more rope winding hoist), only 1 set of lifting equipment can be completed, avoid the period of ascension brings more complex engineering system and cavern operation, save the investment cost.

In 1958, South Africa began to adopt a multi-rope winding elevator, and was widely used in mines with a height of about 2,000 m. Multi rope winding hoist is a kind of double cone winding hoist, its each drum with a rope plate, make each reel at the same time can be 2 root wire rope, wire rope using multiple wraps, through pulley device after 2 cable connected to the same ascending vessel. Because of the lifting of the cordless rope, the change of the tail rope in the deep shaft has been avoided because the change of the tail rope has caused the increase of the tension of the wire rope too large and the impact on its service life.

Multi rope winding machine has great capacity of ascension, drum diameter smaller, more than double ascension can be used to level, don't need a tail rope device, suitable for deep well promoted many advantages, such as solving the multi rope friction hoist in deep well improve the problems of wire rope, changed the deep well mining of ascension patterns. The technology has been applied in foreign countries, and the application in China is still blank.

Deep coal resources are an important part of China's energy security. Therefore, deep mining will be the future development trend of mining industry. Deep ascension is in deep mining is an important problem to be resolved, due to the high stress and high temperature km deep well of the special geological environment, puts forward new requirements to improve transport equipment, and also puts forward new challenges to technical personnel. How to exploit and transport deep coal resources safely, efficiently and cheaply will be a major technical problem that China's coal mining industry needs to break through.

5. Current situation of domestic hoist industry

Throughout the history of China's elevator, from single rope winding type to multi rope friction type, straight from the reducer drive to the motor and spindle drive way, hoist the r&d and manufacturing has made considerable progress.

In recent 10 years, domestic hoisting machine always occupy the absolute advantage in the domestic market, the price factors and relevant national policies, but also objectively reflect the domestic market of domestic equipment of high dependency. Although the imported equipment quality is good, but the price is high, the user pays more attention to the cost performance of the product. In recent years, the improvement of the performance and quality of domestic hoist has promoted its market share.

The current domestic production of the mine hoist enterprises mainly include citic heavy industry, Shanghai metallurgical mining machinery factory, shanxi new rich gave birth to machine manufacturing company, sichuan mining machinery group co., LTD, jinzhou mining machinery group co., LTD. And chongqing taifeng mining machinery co., LTD., etc.

With the rapid growth of coal production, the demand of the mine hoist is also increasing, ABB and the mechanism of promoting west marg company has been established in China to build base, in order to expand the domestic market by reducing manufacturing costs, exacerbated by the mechanism of promoting domestic industry competition strength. Multinational company's products in reliability, intelligence, automatic control, etc, represent the manufacture level of the technology of modern lifting equipment, elevator manufacturing also motivates the domestic market, the idea of design, optimization design method, explore ideas, continuous innovation to adapt to market requirements.

It is worth noting that because of the weak industrial base and lack of technological innovation capability in China